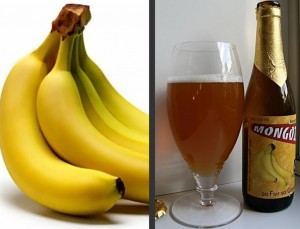

Banana beer is a weak alcoholic beverage made by fermenting bananas with a cereal flour which is popular throughout Africa. The alcohol content is about 4.8% alcohol by volume. This type of beer is produced and consumed in Kenya, Uganda, and Tanzania. The leavening agent is sorghum, millet or maize flour. It is sweet and slightly hazy with a shelf life of several days under correct storage conditions. The processing method and ratio of ingredients used varies widely from country to country and with personal taste. In Kenya, banana beer, made from sorghum or millet flour, is known as urwaga. In Uganda, banana beer is known as lubisi. This technical brief describes one traditional method, and suggests ways in which the hygiene and safety of the product can be improved.

Banana beer is a weak alcoholic beverage made by fermenting bananas with a cereal flour which is popular throughout Africa. The alcohol content is about 4.8% alcohol by volume. This type of beer is produced and consumed in Kenya, Uganda, and Tanzania. The leavening agent is sorghum, millet or maize flour. It is sweet and slightly hazy with a shelf life of several days under correct storage conditions. The processing method and ratio of ingredients used varies widely from country to country and with personal taste. In Kenya, banana beer, made from sorghum or millet flour, is known as urwaga. In Uganda, banana beer is known as lubisi. This technical brief describes one traditional method, and suggests ways in which the hygiene and safety of the product can be improved.

How to make Banana Beer

Ingredients:

- Ripe bananas

- Boiled water

- Roast ground cereal

Equipments:

- Knives

- Filter bags (cotton cloth)

- Fermentation vessel (plastic bucket)

Raw Material Preparation

Ripe bananas (Musa spp.) are selected. In the rainy season unripe bananas can be left to finish ripening laid on a hurdle over the fire where the cooking is done. During the dry season bananas can be ripened by making a pit in the ground, covering the sides of the pit with green banana leaves, packing the bananas in to the pit and then covering them with banana leaves and earth. On one side of the pit a little ditch should be dug for a fire so that warmth and smoke can enter the pit. This takes about six days. The bananas should then be peeled. If the peels cannot be removed by hand then the bananas are not sufficiently ripe.

Processing

The first step is the preparation of the banana juice. The extraction of a high yield of banana juice without excessive browning or contamination by spoilage micro-organisms and proper filtration to produce a clear product is of great importance. Grass can be used to squeeze the banana so that only a clear juice is obtained. The residue will remain in the grass.

One volume of water should be added to every three volumes of banana juice. This makes the total soluble solids low enough for the yeast to act. Cereals are ground and roasted and added to improve the color and flavor of the final product. The mixture is placed in a container, which is covered in polythene to ferment for 18 to 24 hours. The raw materials are not sterilized by boiling and therefore provide an excellent substrate for microbial growth. It is essential that proper hygienic procedures are followed and that all equipment is thoroughly sterilized to prevent contaminating bacteria from competing with the yeast and producing acid instead of alcohol. This can be done by cleaning with boiling water or with chlorine solution. Care is necessary to wash the equipment free of residual chlorine, as this would interfere with the actions of the yeast. Strict personal hygiene is also essential. For many traditional fermented products, the microorganisms responsible for the fermentation are unknown to scientists. However, there has been research to identify the micro-organisms involved in banana beer production. The main micro-organism is Saccharomyces cerevisiae which is the same organism that is involved in the production of grape wine. However, many other micro-organisms were identified. These varied according to the region of production. After fermentation the product is filtered through cotton cloth.

Flow Diagram

Raw materials Ripe bananas

|

Peel Peel by hand

|

Remove residue Use grass to knead or squeeze out the juice. The residue will remain

|

Mix with water The water: banana juice ratio should be 1:3

|

Mix with cereal flour Mix with ground and roasted cereals to local taste. For sorghum the ratio should be 1:12

|

Ferment In plastic container. Leave to ferment for 18 to 24 hours.

|

Filter Through cotton cloth

|

Pack In one-liter plastic bottles with cork stoppers or equivalent

|

Store

Packaging and Storage

Packaging is usually only required to keep the product for its relatively short shelf life. Clean glass or plastic bottles should be used. The product should be kept in a cool place away from direct sunlight.

Improved Method for Banana Beer

The process can be made more hygienic and the quality of product improved by following a typical method for making a fermented beverage. This involves the preparation of a wort (which is a boiled starter substrate), addition of a commercial source of yeast, fermentation under controlled conditions (time and temperature) followed by pasteurization to stop the fermentation. The product made by this improved method will have a different taste and appearance to the ‘live’ beer produced by the traditional method. The improved beer can be bottled and stored and will be consistent from one batch to the next.

Sources: The Technical Centre for Agricultural and Rural Cooperation; Photo: board.muse.mu